Flanged Immersion Heater for Water Supply Application

Flanged Immersion Heater for Water Supply Application

November 22, 2022

Please wait while we gather your results.

Related Articles

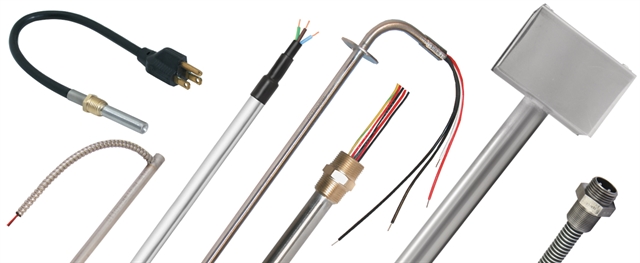

Explore the construction, uses and benefits of Tempco's cartridge heaters and discover how they can work for your industrial application.

An OEM who manufacturers liquid filling equipment came to Tempco for help meeting their end user's application material flow rate.

Tempco's industry knowledge and accessibility led a vendor in the food and beverage industry to choose us as their trusted supplier for the first time.

Within a few weeks of each other Tempco quoted and manufactured strip heaters that exceeded the previously manufactured maximum lengths of both our Channel Strip Heaters and Finned Channel Strip Heaters.