Ceramic Band Heater Replaces Cast-In Heater

Ceramic Band Heater replaces Cast-In Heater

November 17, 2020

Please wait while we gather your results.

Related Articles

Get even heat for oils and non-corrosive fluids. Aluminum-finned Flanged Immersion Heaters provide safe, even heat.

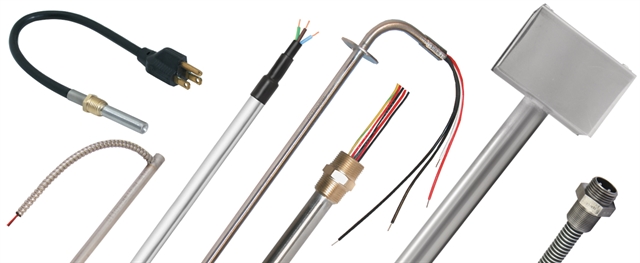

Explore the construction, uses and benefits of Tempco's cartridge heaters and discover how they can work for your industrial application.

Tempco utilized flow simulation software to assist in the discovery, design and manufacture of the ideal circulation heaters for a customer's test setup.

Tempco designed and manufactured silicone rubber heaters to be used as freeze protection for fuel tanks in Mark 7 Go Fast Boats.