Cast-In Thermal Platens for Wave Solder & Reflow Surface Mount Equipment

Cast-In Heaters for Wafer Processing

Please wait while we gather your results.

From the Blog

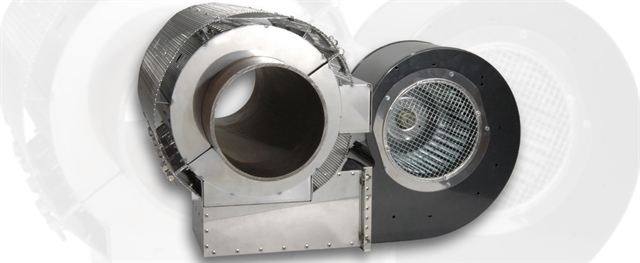

Air-Cooled Shroud Systems: Efficient, Safe, & Custom

Tempco’s guide to air-cooled shroud systems shows how to improve efficiency, reduce costs, enhance temperature control, & boost safety with easy setup & energy savings.

Read More...

Sand Molds and Their Crucial Role in Casting Quality

Learn how investing in high-quality cast-in heater molds & precision heater patterns improves production efficiency, reduces defects, & boosts customer satisfaction.

Read More...

Heating Hydraulic Oil with Tempco Cast-In Circulation Heater

Tempco utilized flow simulation software to assist in the discovery, design and manufacture of the ideal circulation heaters for a customer's test setup.

Read More...

All About Tempco's Shroud Systems

Improve efficiency in your extrusion process with Tempco's Air-Cooled Shroud Systems constructed with either sheet metal or cast aluminum.

Read More...